Knowing what questions to ask can help when determining the correct forklift

Always begin the process of selecting a forklift rental by confirming you have a properly trained and certified operator with a valid license. Herc Rentals offers operator training.

Renting a forklift for your jobsite is easy but each forklift has limitations in the amount of weight it can lift, and how high it can carry or lift a load. As more forklift options and attachments become available, it is increasingly important for forklift operators to have a clear understanding of their forklift’s load capacity and the risks involved in exceeding it. Understanding the type of forklifts, weights of available attachments and forklift load capacities will go a long way toward improving the equipment’s efficiency and preventing serious injury.

First, ask yourself these questions:

- How heavy is my typical load?

- How high do I need to lift my loads?

- How wide is my common aisle space?

- How many hours will my forklift be used per day/per week?

- Will my forklift be used indoors or outdoors?

When selecting a forklift, you’re likely to encounter forklifts that are categorized by standard, mid and high capacity. So, what exactly is a forklift’s load capacity?

Load Capacity: The maximum weight a forklift can safely carry at a specified load center.

Load Center: The horizontal distance from the vertical face of the forks to the center of the gravity load.

As a general rule, the load center is 24-inches from the face of the forks or the center point of a 48-inch by 48-inch pallet. If a load is not centered at the precise position, then a forklift’s capacity will be reduced.

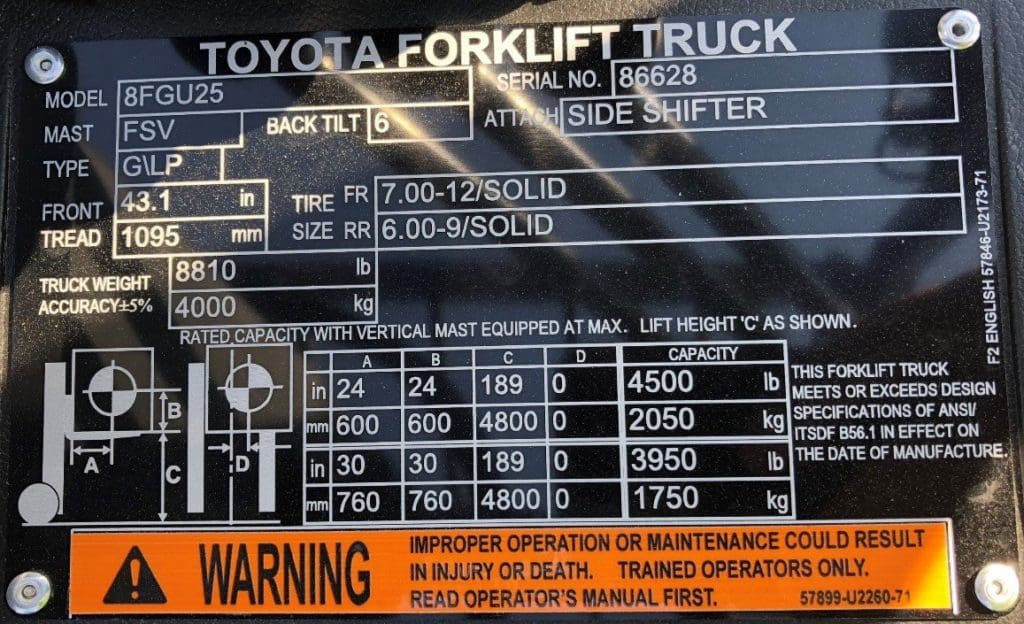

To get a better understanding of what a forklift can or can’t do, operators should look to the equipment’s load capacity data plate, usually located on the instrument panel near the operating controls. The data plate or capacity plate includes important information about the forklift such as the model, the type of mast, fuel type, tire size, weight and load capacity. Additionally, the plate specifies the load each forklift can safely lift at different mast angles or when the forklift is fitted with an attachment.

The key in finding the right forklift with the right load capacity begins by knowing what you’ll be lifting and how often. A forklift’s efficiency is directly linked to how you plan on using its lifting power. For example, if your load capacity is rated for 4,000 pounds, that is the most you can safely lift. However, if you’re constantly lifting maximum weight, you’ll be putting a lot of stress and energy on the machine. It’s best to select a forklift with a greater load capacity than you’ll actually need.

A forklift with a larger load capacity than what you need to lift can also prove beneficial if you decide to add an attachment. Obviously, adding an attachment reduces the lifting capacity of the forklift due to the weight of the attachment itself and because an attachment typically moves the equipment’s load center forward. As the center of gravity moves forward, the maximum load weight must decrease to prevent tip overs.

That’s why it’s important for forklifts to have rated and de-rated capacities.

De-rating: A term used to describe the decrease in a forklift’s nominal capacity.

For example, the higher the lift, the deeper the load center, or with the addition of attachments, the greater the de-rating becomes. That’s why when you rent a forklift, it’s important you have access to information regarding the de-rated capacity of the forklift when an attachment is fitted. To be on the safe side, it’s always good to speak with a Herc Rentals material handling expert before adding an attachment, and always refer to the forklifts data plate.

One last thing to take into consideration when it comes to load capacity are the lift heights of a forklift. A forklift with a high mast has a greater carrying capacity at lower lift heights, therefore, forklifts with high masts may have a dual capacity rating at the maximum lift height, allowing the forklift operator to work with heavier loads at low heights.

For more information on the types of forklifts available, click HERE.

How To Read A Forklift Data Plate

(Top to Bottom Rows, left to right)

- Model Number: This is important for relaying information about repair, technical issues, understanding lift capacity and more.

- Serial Number: Important for technician communication.

- Mast Type: Forklifts feature various mast types including 2-stage (F or FV), 3-stage (FSV) and 4-stage (Quad) that vary depending on specific forklift model.

- Back Tilt: This number represents the degrees back the mast can tilt to help keep loads on the forks securely. In this instance, it’s six degrees.

- Attach: This lets operators know what attachments have been added to the forklift. It gives operators a clear indication of its capabilities. In the example above, it’s a side shifter. If an attachment is not called out on a data tag on the forklift, that attachment can’t be run on the equipment. Forks are the exception. They will not be called out in this section. This is important because attachments affect the rated operating capacity of the machine making it less stable.

- Type: This shows the fuel type. In this instance it’s gas or liquid propane. Other types include (E) electricity, (DS) diesel and (CNG) compressed natural gas.

- Front Tread: The front tread of a forklift is equivalent to its overall width. This provides operators with the knowledge of the space the forklift will take up in the working environment.

- Tire Size: This is the size and type of tires. “Solid” means a solid pneumatic tire. Cushion type tire will indicate “smooth” or “treaded”. Tire size can affect rated operating capacity and is important when calculating ground pressure.

- Truck Weight: Overall weight of the forklift. This is important for trailer transport of the forklift from one jobsite to another and more.

- Forklift Diagram: This provides several data points important for understanding the function of your rented forklift. This is designed to help you understand what the forklift can lift and how it maneuvers on your jobsite.

- Column A tells you the load

center used in calculating the reduced (option specific) rated operating

capacity.

- Note: On this specific machine (while a 5K model) is only rated at 4,500 lbs. Options that reduce overall capacity include the FSV mast (heavier than standard mast) and the side shifter (attachment adds weight, pushes the load backrest further away from the forklift and side shifting moves the load left and right (off center or balance). Additional options like a quad mast or fork positioners will also cause the rated operating capacity to reduce. Tires could also negatively impact the forklift’s capacity.

- Diagram A (on the left) shows how far the center of the load is from the loads back rest. When considering forks, double the length of Diagram A to calculate the length of the forks. You must have a data plate that matches half the length of the forks with the exception of 42” or smaller. Use 24” load center for these.

- Column B is how high off the forks the center of weight of the load is. When not square, calculations can be made to adjust rated operating capacity and should be noted on the data plate Column D for the specific application.

- Column C is the maximum fork height of the mast. In this case, it’s 189-inches. This is the place where the load is the least stable. In the column on the far right named Capacity, note how pushing load center out 6 inches (24- to 30-inches) on this machine affects its overall rated operating capacity by 550 lbs.

Forklift Safety Tips

- Rent forklifts with a slightly bigger load capacity than what is actually needed.

- Estimate the safe load capacity with oversized loads.

- If the stated load center is exceeded, then counteract this by reducing the weight of the load.

- Ensure that the load capacity data plate is legible, fitted and correct.

- Know the capacity of your forklift and never exceed it.

- Check the marked weight of an object, alternatively use a scale to weigh loads.