“They have stoked the furnaces and hurried the factory wheels. They have made the planes and welded the tanks, riveting the ships, and rolled the shells.” – President Franklin Delano Roosevelt

Five thousand years after metal was first joined together through a process known as forge welding (heating metal until it is soft and then joining them with a hammer), welding continues to play a vital role in keeping people safe and improving their quality of life.

Each April, the American Welding Society (AWS) and a diverse welding community of technicians, manufacturers, and more celebrate National Welding Month to increase awareness of the welding industry, its wide range of available career paths, as well as new innovations and advancements in welding gear.

Throughout the month, the welding community, which contributes to the construction of buildings, cars, aircraft, machines, ships, space stations, and more, focuses on new ways to promote the skill and tools of the trade.

National Welding Month also presents welding equipment manufacturers and equipment rental companies with opportunities to highlight welding gear, its uses, and how to determine the correct welder for specific uses.

Here are some hints to help find the right welding gear.

Herc Rentals offer the latest and most widely-used gear. With electric, gas, liquid propane, and diesel welders in its fleet, metalworkers can find precisely what they need for a job.

Electric welders up to 650 amps

- Multi-Purpose or Inverter welders can be used as single units or several units can be installed in racks for multi-operator use.

- The CST-280 CC Inverter is the smallest and is capable of stick welding.

- Higher amperage CC/CV welders (350/450/650 amps) are multi process, capable of Stick, MIG, TIG, Flux Core and Arc Gouging.

- Often overlooked, electric welders can be powered by large generators which can be more economical vs. using multiple engine drive welders.

Gas and liquid propane (LP) welders up to 300 amps

- Smaller footprint that the larger diesel welders so more portable. Usually have a wheeled undercarriage or can be highway trailer mounted

- Multi-process (Stick/MIG/TIG/Arc Gouge)

- The advantage of LP over gasoline is the elimination of the possibility of fuel spills during refueling. More recently, LP is being used on conveyor system installations in large distribution centers.

- If an LP welder is being used in a confined area, anywhere there are walls and a roof even if there are open doors/bays, the possibility of CO poisoning is very real. The use of a fan is required by ANSI anytime an internal combustion engine (diesel, gas or LP) is used in a confined space.

Diesel welders up 300/400/500 amps

- Usually trailer mounted for jobsite mobility, but can be skid mounted

- Multi process (Stick/MIG/TIG/Arc Gouge)

- Have 10kW generators for providing power in the field. These are the work horses of the welding fleet.

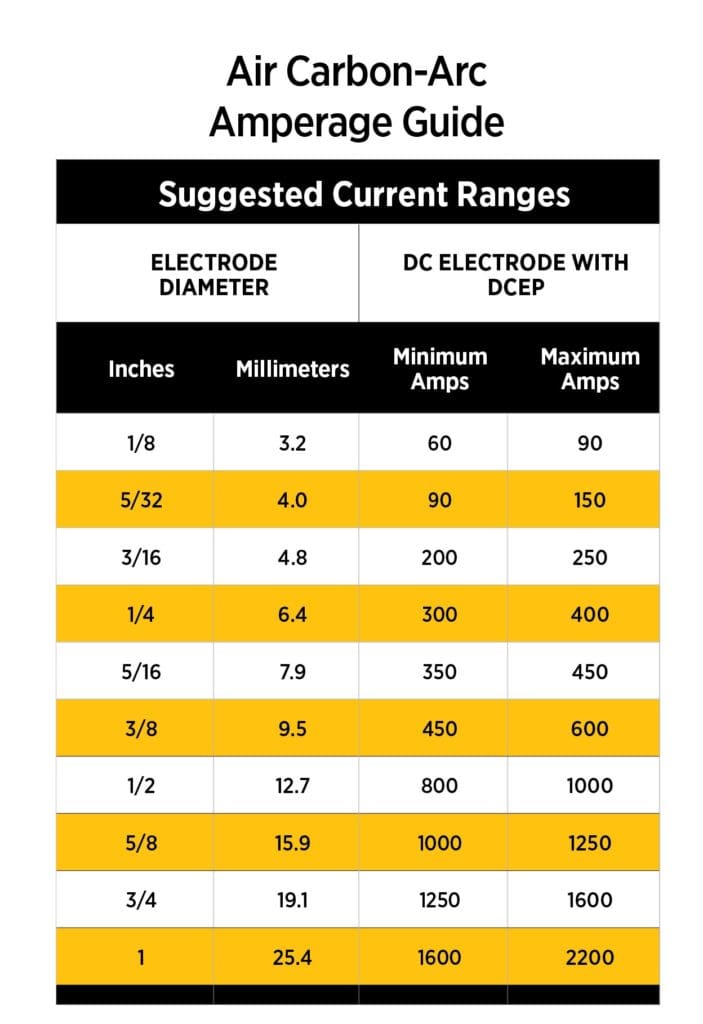

Another thing to consider when selecting a welder is matching the amperage of the welder to the welding process to be performed. Too often, customers will request the highest amperage welder when it’s not always needed. Just because a customer may be gouging, doesn’t mean they always need a 500-amp diesel welder. What dictates the amperage is the size of the caron arc rod being used (see below). Additionally, some still think using a lower amperage welder could damage the unit when gouging. This may have been the case 20 years ago, but new technology has eliminated this issue by way of thermal breakers.

Pro Tip: When customers arc gouge, a lot of times only a small percentage of the work needs to be done with the welder. Customers often spend more money renting high amperage output welders when they only need the max amps 20% of the time. A more cost-efficient means to achieve higher amperage for intensive arc gouging applications is to parallel two welders. Just like generators, this involves connecting two machines via cables together to double the amperage output. Paralleling can be done with either electric or engine drive welders. For example, two CST-280 electric welders paralleled could provide up to 560 amps of arc gouge power. That’s more affordable than a 500-amp diesel! For more information about paralleling for high amperage arc gouging capability, contact your local Herc Rentals representative today.

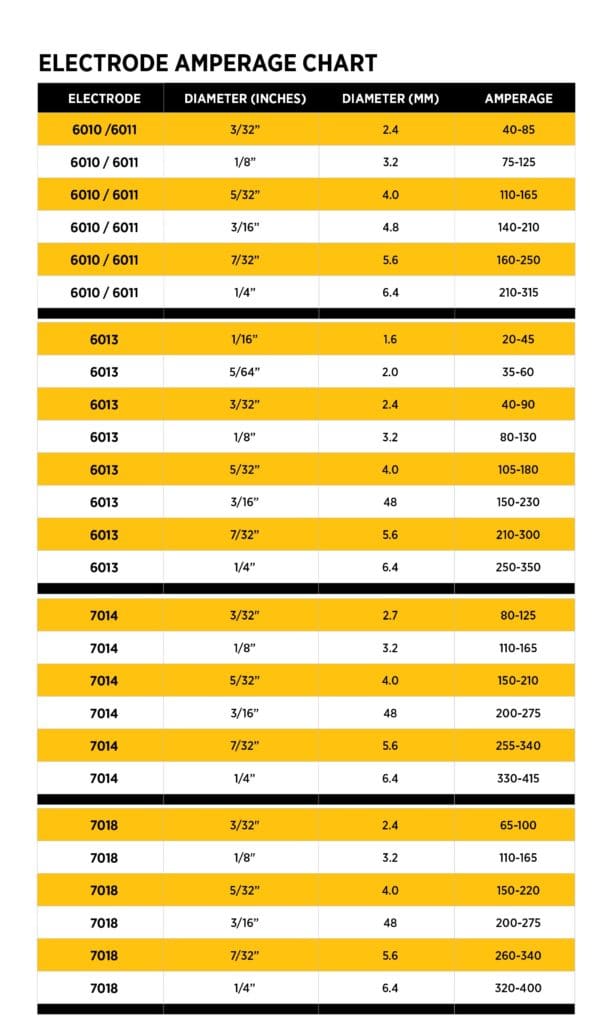

Additionally, selecting the correct welder should be based on the size of the electrode if Stick welding and the diameter of the gouging rod if Arc gouging. For more information about sizing, contact your local Herc Rentals representative or consult the electrode amperage charts and Arc amperage charts below.

For more on National Welding Month, including special events, welder discounts, instruction, and more, visit the American Welding Society.